Blog AI Influenced Machine Controls

Tasks that used to require human analysis and actions have been replaced by AI systems that intelligently analyze and react to conditions. Optical sensors, camera systems, and machine learning have replaced the need for constant monitoring by machine operators, allowing for more autonomous operations and a more secure process, especially when operating in lightly manned shifts.

Optical sensors, camera systems, and machine learning

The impact of vision systems using optical sensors and camera systems has greatly expanded the use of AI capabilities within the controller. An operator’s ability to visually monitor conditions has always been an important aspect of machine operations and has traditionally been the first response mechanism to correcting faults during operations.

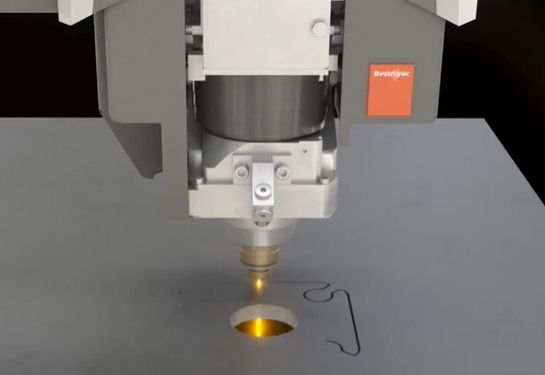

Now optical sensors and cameras have been incorporated into machine vision systems and control logic to dynamically monitor and act upon conditions as they occur. Measurements and analysis are instantaneous and corrective actions occur on-the-fly, which is much faster than what could be detected and corrected by an operator.

Optical sensors can measure the visible light being emitted within the laser cut kerf and determine if it is in the correct range for proper cutting conditions for that material. The optical sensors can also be used to gradually increase process speeds. Then once a threshold is reached, the control will reduce the speed slightly to maintain the optimal cutting conditions without cut interruptions.

Optical camera vision system

When the intensity of the visible light increases beyond a specific threshold, the optical sensors instantly detect this as a deterioration of a cut condition and will automatically stop and re-cut where the condition occurred at a slightly reduced speed. If the fault continues, then the machine will automatically perform a nozzle inspection using an optical camera vision system to not only detect the condition of the nozzle but also the centering of the nozzle.

If required, the system will replace the nozzle and also perform an automatic nozzle centering and then continue to where the original fault was detected and re-cut the area. The same optical sensor can determine if a nozzle has made contact with an adjacent part and or been bumped off. The system will automatically stop, replace the nozzle and re-center the nozzle and continue with the next cut feature.

Optical cameras can also be used to determine how the sheet has been placed onto the shuttle table. There are many variables to sheet positioning including the shifting of sheet stacks in the X or Y direction from either the truck transportation or forklift driver handling.

Using an optical camera vision system attached to the motion system, the edges of the sheet in X a Y will be detected as well as the angle at which it is positioned relative to the table. The machine control then automatically re-orients the program to the new x and y edges and skews the program to the angle of the sheet placement.

Parameter wizard machine learning

Many times operators are tasked with finding a new material parameter for a material they do not have in their library or because it is of a different quality than normal. This manual process of finding parameters is often time-consuming for operators. A machine learning parameter wizard is a system that will use a set cut program and will set five different cutting conditions for a new parameter.

After cutting the five samples, the operator uses a Star rating system from one to five, five being the highest. The wizard automatically analyzes the results of the ratings and creates a new and improved set of five cutting conditions and the process of operator evaluation continues. This process repeats up to five times max or before if there is no difference between the five-star sample and the four-star sample. The parameter wizard machine learning system greatly reduces the time spent finding new parameters and increases the quality of the new parameter.

AI will continue to influence machine control technologies in the future, enabling additional automated monitoring, analysis, and actions to be enacted on the fly as they occur. These systems are already in use to secure the operations of highly automated laser cutting systems with material automation and sorting systems in lightly manned shifts. Reducing the time that operators spend on mundane monitoring tasks is better suited for AI-influenced monitoring systems that can react much faster than humans. As AI technologies continue to evolve so will machine control systems, enabling higher levels of automated systems to also evolve over time.