Green steel from toxic red mud

CO2-free iron from aluminum waste

CO2-free iron can be produced from aluminum production waste using hydrogen. The process would also be economically worthwhile.

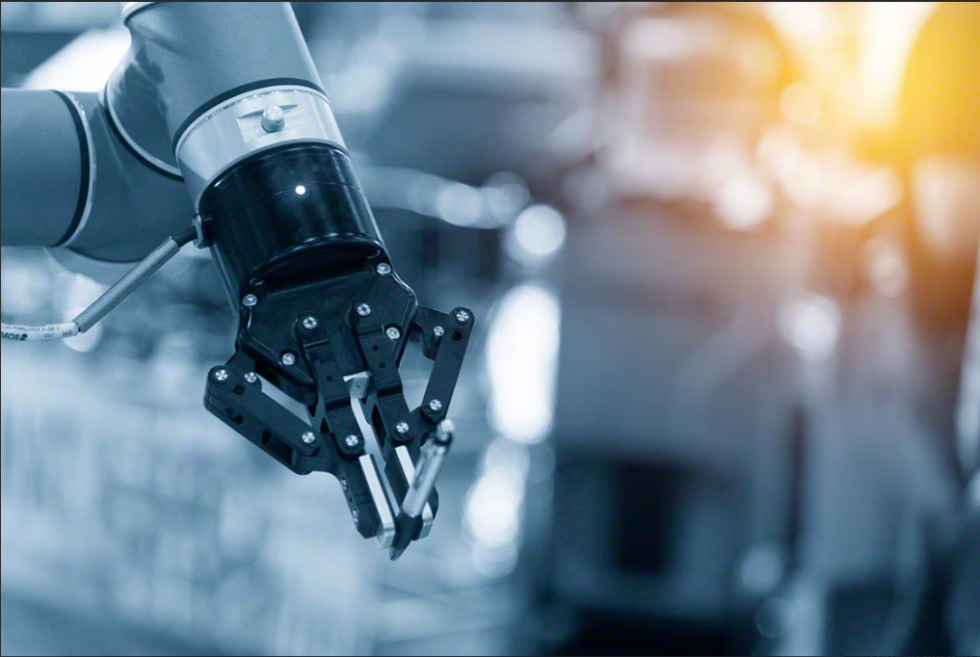

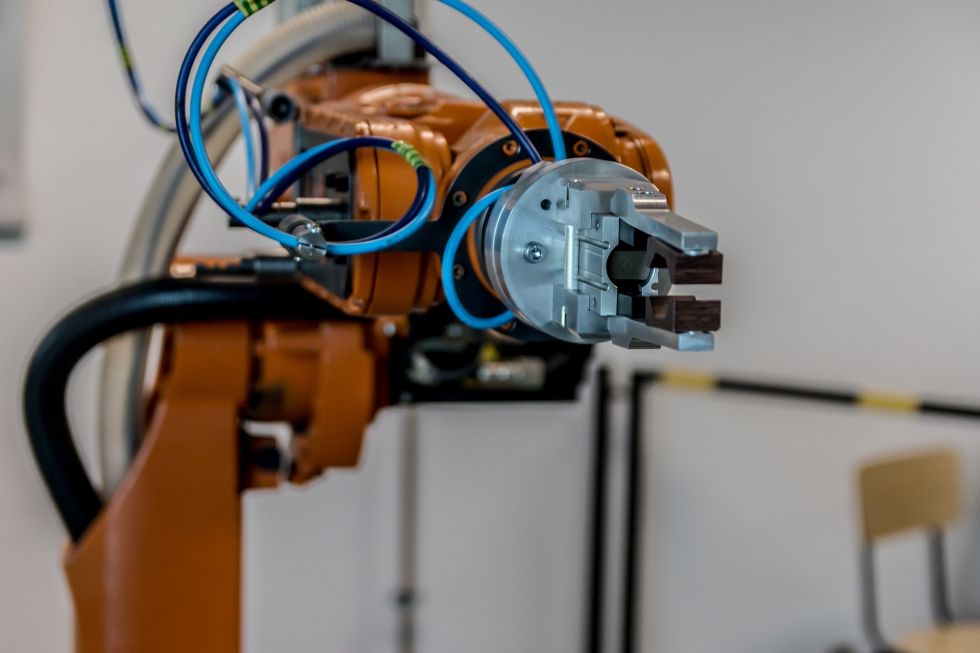

The production of aluminium generates around 180 million tons of toxic red mud every year. Scientists at the Max Planck Institute for Iron Research are now showing how green steel can be produced from the waste from aluminum production in a relatively simple way. In an electric arc furnace, as used by the steel industry for decades, they convert the iron oxide contained in the red mud into iron using hydrogen plasma. The iron is so pure that it can be processed directly into steel.

In this way, almost 700 million tons of CO2-free steel could be produced from the four billion tons of red mud that have accumulated worldwide to date. This corresponds to a good third of annual steel production worldwide. And as the Max Planck team shows, this process would also be economically worthwhile.

“Our process could simultaneously solve the waste problem of aluminum production and improve the carbon footprint of the steel industry,”

says Matic Jovičevič-Klug, who played a key role in the work at the Max Planck Institute for Iron Research.