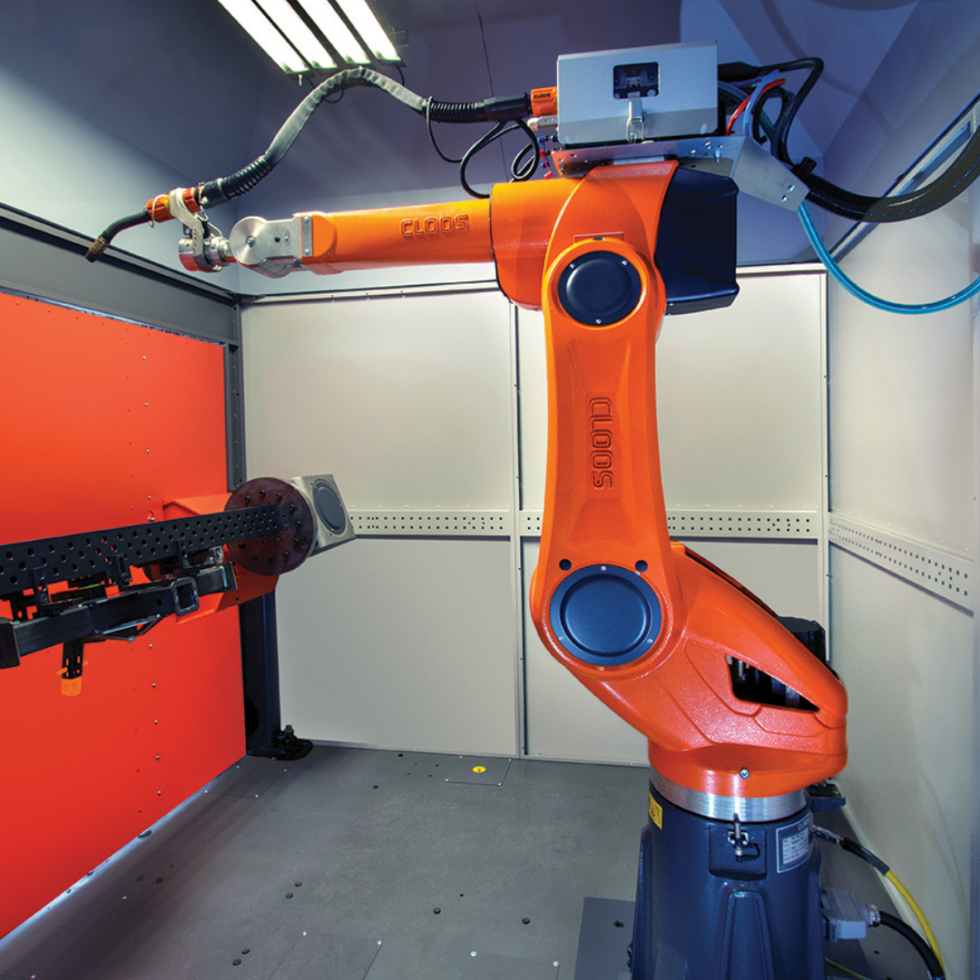

News Bystronic Robotic Welding Cell powered by CLOOS: The Customized “Ready to Weld” Solution for Automated Robotic Welding.

Debut at Competence Days

At the Competence Days for the Americas, Bystronic Inc. introduces the first Bystronic Robotic Welding Cell powered by CLOOS into the US market. CLOOS, with headquarters in Haiger, Germany and with offices in Schaumburg, IL will supply the Bystronic Robotic Welding cells and provide installation, training and service, while Bystronic will be responsible for the sales and distribution of these machines. CLOOS manufactures the robot weld positioner, the robot controller, the welding power source, and the cell integration. CLOOS also maintains its own powerful and user-friendly offline programming software, RoboPlan QRP Professional, for fast and easy programming.

Bystronic will offer three specific robotic welding cell models powered by CLOOS; Micro Cell, Compact Cell and Compact System, each having a specific scope of application based on the size and weight of the parts to be welded, and each with a 2-station work piece positioner. The Micro Cell features an overall clamping length of 55 inches and a nominal load capacity of 280 lbs. per side for the manual rotating work piece positioner, and a 400A welding power supply. The Compact Cell features an overall clamping length of 61 inches and a nominal load capacity of 562 lbs. per side for the automatic rotating work piece positioner, and a 450A welding power supply. The Compact System features an overall clamping length of 138 inches and a nominal load capacity of 2248 lbs. per side for the automatic rotating work piece positioner, and a 450A welding power supply.

All welding cell models maintain an integrated safety system including nozzle search and anti-collision sensors, interlocked doors, safety enclosures with operator window, and when required, safety fencing and light curtain barriers. The Compact Cell and Compact System models include automatic Thru-Arc Seam Tracking for maintaining weld seam centering and integrity. The integrated forklift pockets for the Micro Cell and Compact Cell enable a quick installation enabling a fast “ready to weld” integration into a customer’s production environment.

About CLOOS Robotic Welding, Inc.

Since 1985, CLOOS Robotic Welding, Inc. Schaumburg, IL, has been providing customized automated turnkey welding solutions throughout North America. Components are designed, developed and fabricated exclusively by CLOOS to ensure optimum compatibility. At CLOOS their goal is to assist their customers in reaching their manufacturing objectives by developing personalized, turnkey automated welding solutions. With CLOOS, you are ensured that you will receive the best result for all your manufacturing welding needs. All components for your arc welding project are designed and manufactured by one company. CLOOS.

CLOOS not only builds the highest quality and long-lasting equipment; but also engineers, researches and develops it, provides know-how transfer, training and service to their customers, making CLOOS the ideal partner for all your arc welding needs. CLOOS Robotic Welding, Inc. in Schaumburg, IL has also maintained a subsidiary located in Monterrey, Mexico since 2001.

CLOOS Robotic Welding, Inc. is a subsidiary of Carl Cloos Schweisstechnik GmbH located in Haiger, Germany which was founded in 1919 and where today has more than 800 employees developing and manufacturing the CLOOS product range.