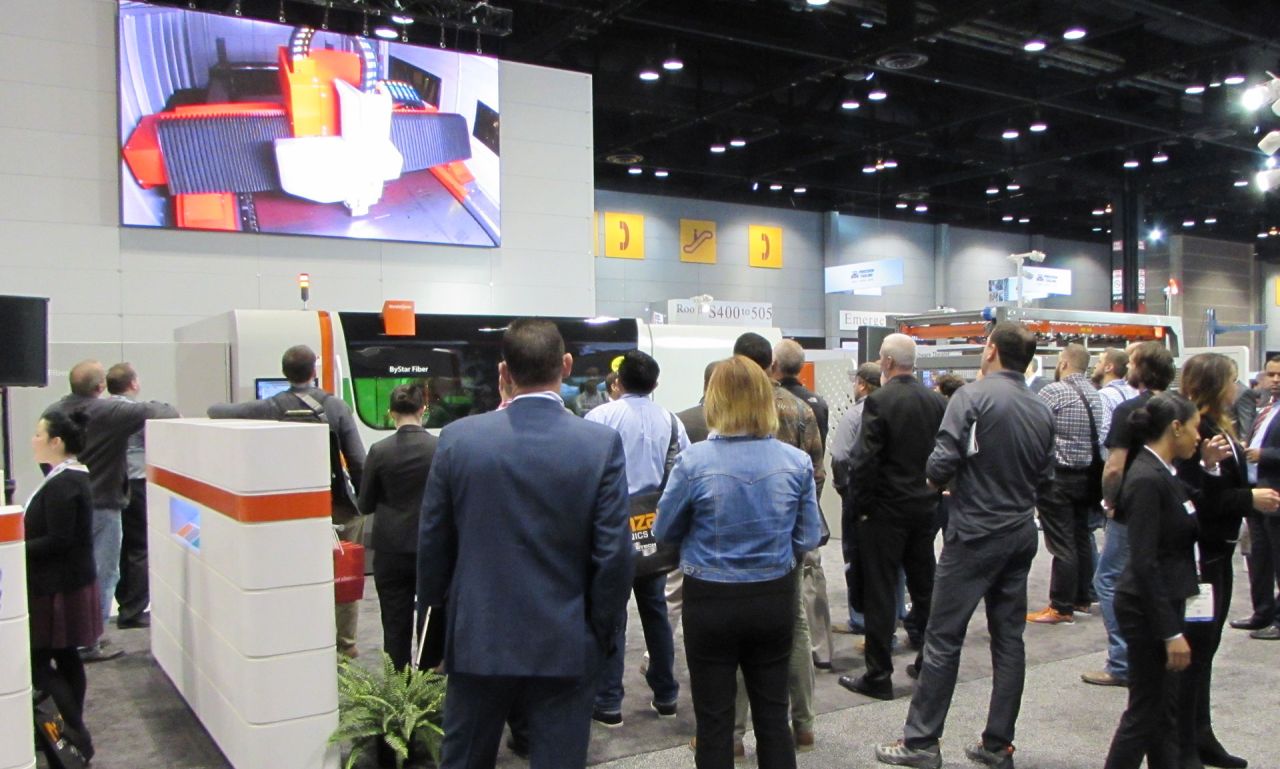

News FABTECH 2019: Enter the Bystronic World of Innovation

The Future of High Performance Manufacturing

At Booth A2122, Bystronic will present new high-performance solutions that cover the full spectrum of file-to-part manufacturing - laser cutting, bending, automation, and software technologies that are driving fabricators to new levels of productivity, profitability and success.

The innovative ByStar Fiber with NEW 12kW Fiber laser has an expanded spectrum of cutting applications for exceptional speed and cutting quality, from thin sheet to thick plate edge. Bystronic has developed the innovative BeamShaper function. BeamShaper allows for an ideal adjustment of the laser beam profile to cut thick steel plate with diverse material characteristics. In steel materials up to 1.125 inch, the new function raises the quality of the cut surface and increases the cutting speed by up to 20 percent when cutting with oxygen.

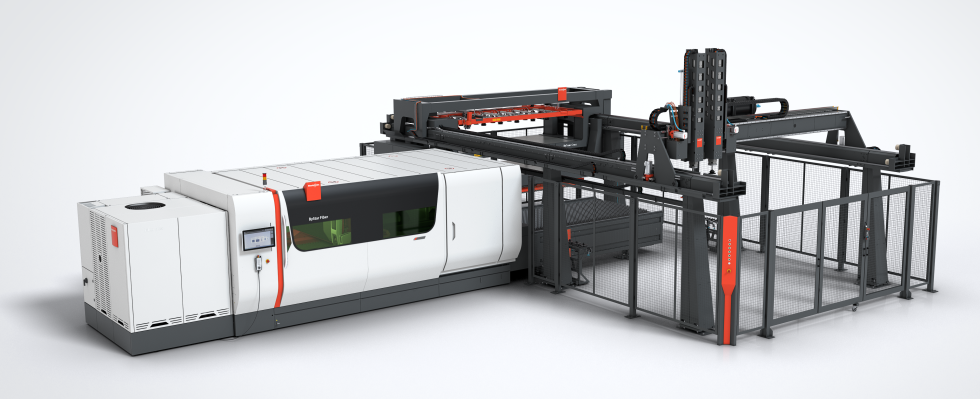

High machine dynamics and process reliability ensure uncompromising high-end performance and unparalleled high parts output. The ByStar Fiber 3015, with 12kW will be shown with the NEW BySort, an enhanced solution optionally available on the NEW ByTrans Cross modular material handling system that fully automates the sorting of parts.

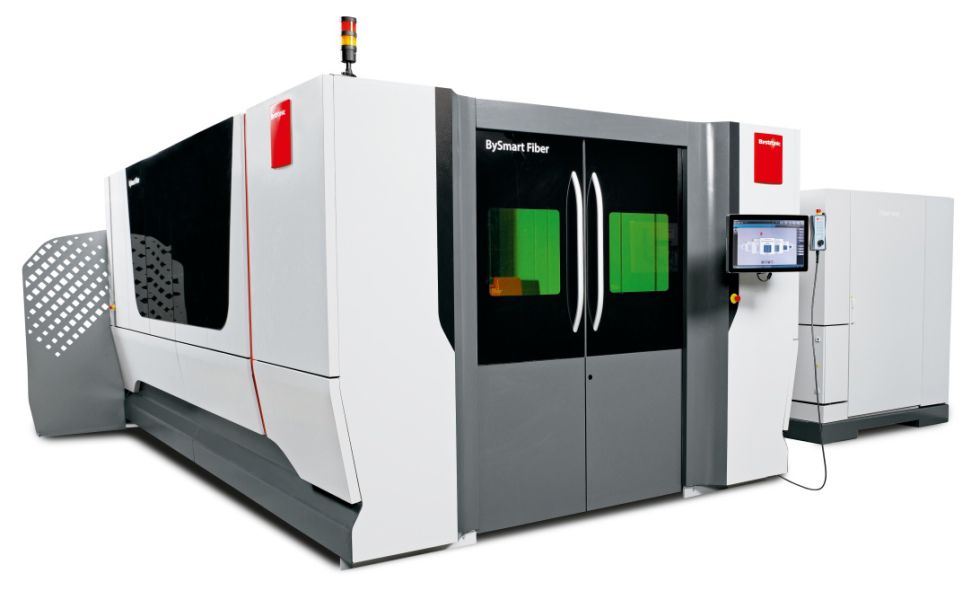

The next generation BySmart Fiber 3015 with 6kW Fiber laser opens up the full potential of Fiber lasers to fabricators who want to gain a competitive edge with innovative technology and performance at an affordable price. The BySmart Fiber 3015 will be shown with the ByTrans Extended compact material handling system.

Bystronic’s NEW tube laser cutting solutions offer the widest range of automated 2D and 3D cutting systems for the flexible production of small and large series tubes and profiles.

The availability of 2D and 3D laser cutting technology opens up the possibility of individually customized and precise cutting of a wide variety of shapes-- also profiles with diverse cross-sections and bevel cuts of up to 45 degrees.

Based on the popular Xpert press brake, the NEW Xpert Pro press brake offers a modular design that increases the flexibility of add-on options for unmatched speed and productivity. With the Xpert Pro, Bystronic presents a high-end press brake that sheet metal processing companies can adapt to their requirements on a modular basis. Shown will be the Xpert Pro 150 Dynamic Edition.

The NEW Xpress 50 press brake is a compact, affordable bending solution with intuitive operation, employing Bystronic’s proven ByVision Bending Control technology.

Compact, modular machine design and additional functions support individual customization to the production environment. High machine rigidity offers ample space for a wide range of bending applications.

The Xpert 40 with Mobile Bending Robot supports today’s fluctuating lot sizes and varying part complexities in a fully flexible automated or manual bending system. Control is seamlessly integrated into the press brake user interface.

BySoft CAM software represents a new generation of design and manufacturing software that keeps pace with high productivity downstream equipment. BySoft CAM offers a comprehensive range of programming. Plant Manager schedules and monitors manufacturing processes efficiently, providing an overview of the production process.

Developed by Bystronic, the ByCockpit App provides real-time analysis and visualization of the data associated with sheet metal processing to enable companies to constantly improve their production.