News Bending in the smartphone era

Do you remember getting your first cellphone? What was the first thing you took out of the box and spent time with? It was probably the user manual. The cellphone was a new technology, and you needed time to understand and learn to use it. It wasn’t intuitive, and you absolutely needed that manual.

What happens when you get a new smartphone today? You unwrap the well-designed package, admire your shiny new device, turn it on, and get started. It’s probably already charged and just waiting for you to use it. That’s it. It doesn’t have any buttons or dials; the entire surface is a human-machine interface, or HMI. And it probably doesn’t have a manual. A pop-up notification shows you received a new message, and you just tap to see what it is. It’s intuitive.

Press brakes last much longer than cellphones, of course. That’s why in many job shops today you might find both mechanical and hydraulic press brakes with old controls (see Figure 1). They can last 30 years or longer and still bend parts. Of course, just because a machine turns on does not mean it can produce parts efficiently. If you see less seasoned operators attempt to run the shop’s oldest brake, you’ll probably hear them say, “Does anybody know how to operate this machine?”

Learning and understanding bending theory is probably as challenging as learning to be a good welder. It takes time and patience to learn the differences between every machine. Those differences can be significant, especially in a bending department with both old and new equipment. They require different training strategies, all driven by technology that has literally changed how operators learn about sheet metal bending: the software and machine control.

The Pre-Smartphone Era

Imagine starting a new job as a press brake operator around the same time that you received your first cellphone, before the smartphone era. You spend most of the time going through the manual, guided by a veteran who knows the machine inside and out. You read the blueprint and adjust the machine settings as necessary. You learn how to adjust the position of each axis, determine where the backgauge needs to be, dial in the part, make other adjustments by typing nominal values into the controller, then run production until you need to switch over to the next part. Once you understand the basic concept of one machine, you walk to the next press brake and learn this process from the beginning again, with your experienced tutor and the manual right next to you.

You receive a printed blueprint, and you write the program at the machine control. You determine the material type and thickness, define your bend angle, then position your backgauges manually for each bend. If not provided on the print, backgauge positions are defined as an actual absolute value that needs to be calculated manually (see Figure 2).

Overall you spend 10 minutes (or longer) getting the press brake ready to make the first bend—and that old machine control gives you no indication of how to do this. By looking at the control alone, you don’t know which tools to pick or how to set them up. That’s why you need an experienced operator by your side. He knows the setups and best ways of doing it by memory. Still, even with all his knowledge and experience, he pays very close attention to his choices so he doesn’t make any mistakes. Setup is time-consuming, and the old machine control doesn’t give much if any assistance.

At some point, you’re on your own. You position the peripherals of the machine first so you know where to place the tools. What tools do you select for this job? You’d better have a quick guide or “little black book” close to the press brake to know which tools to pick.

The Smartphone Era

Fast-forward to today. Imagine you just graduated from school and you’re now looking for your first real job in the sheet metal industry. Thing is, you aren’t on the shop floor with an experienced employee who has operated just one machine his entire career.

Instead, you’re in a classroom environment. You sit by a desktop PC with the press brake operating software installed. You don’t have a printed machine manual, and on some days you might not work with someone with decades of press brake experience, especially if they’re needed on the floor. But that’s not a problem—and here’s why.

The controls come with a built-in guide to help you understand what each command does. The operating system installed on modern press brakes is no different than any desktop PC. In this time of Industry 4.0, manufacturers are keeping up with the latest versions of operating systems like Microsoft Windows 10. The entire system is designed both for security and compatibility. The software can communicate and connect with other equipment, office networks, and the internet.

That’s how you can train on a press brake before even setting foot in a job shop. The software effectively “teaches” you to navigate through an interface of a product that is completely new to you. The HMI has no buttons or dials.

Interesting how familiar that sounds, isn’t it? Smartphones have probably had the biggest impact on the way the industry interacts with machinery. We no longer push buttons or turn dials. There is no need to take a blueprint, adjust each bending step, and define the X value of the backgauge position. In fact, you don’t even see the X value being displayed on the controller. It’s calculated in the background and corrected—no need to manually tweak it.

You operate the control at the machine to produce parts, not to write a program from scratch. With offline programming, you let the CAM software perform all of the functions as it takes the native 2D or 3D model and creates the program automatically. The software determines where to position each axis of the machine based on the part geometry.

The industry has switched from a “passive” HMI with function-specific buttons and dials to an “active” touchscreen displaying a full 3D environment—a shift that mirrors smartphones and other technology we use in modern daily life.

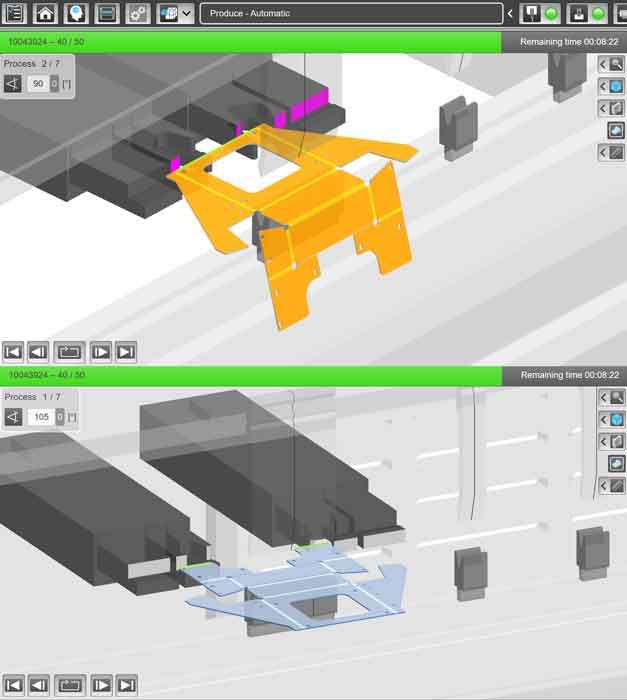

Back in the classroom, you learn how to navigate through the entire machine control. You make an adjustment and the HMI simulates everything you changed, giving you visual feedback. If you change the bend sequence or toolstation positions, you’ll see the HMI conduct a real-time check of any collisions that might occur.

A part with eight bends has 10,321,920 possible bend orders! That’s 20 million possibilities for a collision before and after the bend. Software now checks all possibilities within seconds. If you want to adjust the backgauge position, the control shows exactly how the backgauge will move. The control recalculates every change in real time with a touch of a finger.

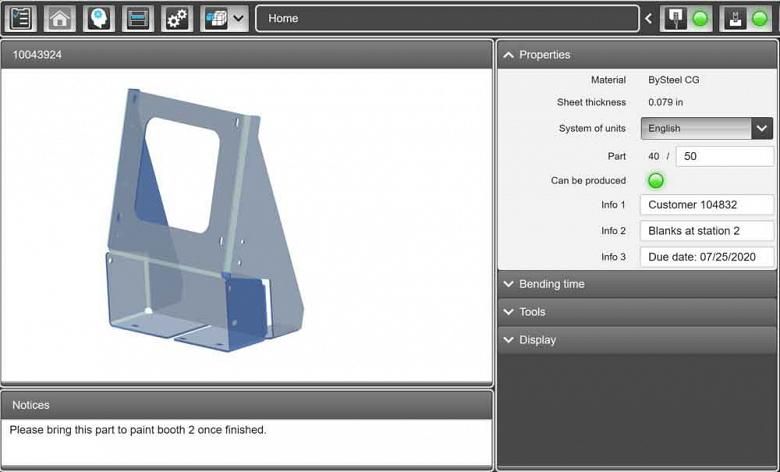

You now have full 3D visualization of the part geometry, originating from the CAD/CAM software, which allows the CNC to calculate each axis position automatically. You also can retrieve other relevant information from the control, such as which customer the parts are for and where the raw material is located (see Figure 3).

How exactly do newer CNC press brakes create more parts than older mechanical or hydraulic press brakes? The real time savings come during setup.

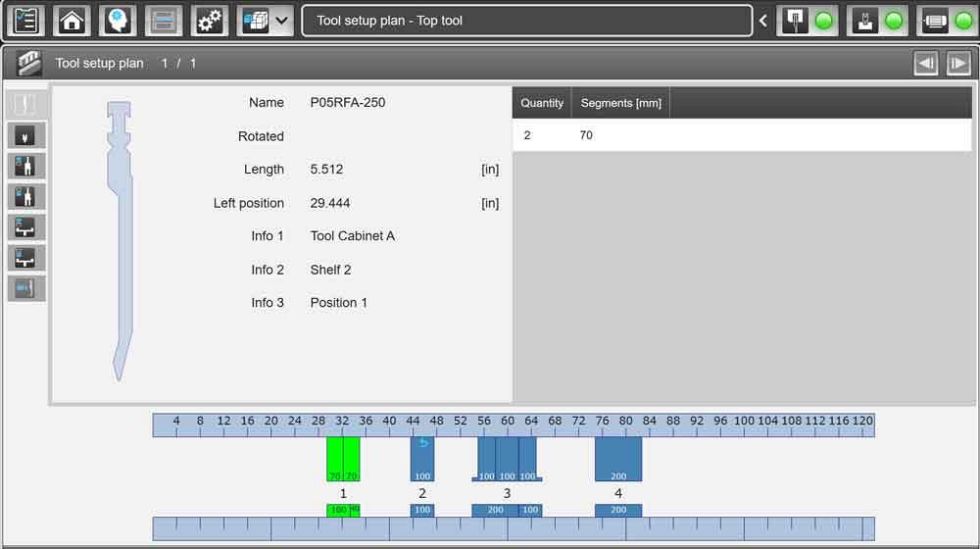

You don’t need to bend part programs for years to know how to set up the job properly. The control guides you through every step. It displays which tools you need at which rotation (facing forward or backward), and, most importantly, where on the machine bed they need to be.

If you’re forming a simple one-bend part, it usually doesn’t matter how long the toolstation is or if it’s offset a little to the left or right on the bed (though of course the punch and die need to be properly aligned vertically). But most jobs require precise tool positioning, especially when bending boxes or complex geometries. If you don’t place tools properly, they could collide with a previously bent flange (see Figure 4).

Ask any press brake operator if they have ever bent a part backward, and they’re likely to say yes—and they probably were operating an older press brake when it happened. It’s an understandable mistake, especially when forming similar-looking parts or when you’re bending two parts that mirror each other.

Controls with 3D graphics help prevent this. They show you every contour of the part, including internal features like holes that can serve as a guide as you hold the part in the press brake. When you see the part’s color change on the controller’s screen, you know you need to flip the part for the next bend (see Figure 5).

A New Start to a Career in Bending

Enhanced HMIs and other technology advancements haven’t changed the bending fundamentals. No matter how old or new a press brake is, the radius during an air bend still forms as a percentage of the die opening. The forming process still elongates the material at the bend, hence the need for software to run those bend calculations. New brakes still use K-factors, bend allowances, and bend deductions; they’re just calculated automatically in the background.

That said, if you start your career at a new press brake with a smartphone-esque control, you’ll learn the job in a new way. Decades ago you would have learned to visualize how a piece folded up. Operating a modern brake, you see a 3D simulation right in front of you. Months and years of experience will give you insights into overall process improvement.

For instance, you might suggest an expansive staged setup that would have been far too time-consuming to perfect on an older press brake, at least for a low-volume job. But automated programming and simulation changes that equation. With years of experience under your belt, you’re now thinking about how bending technology can make the overall operation more efficient.

In essence, the modern press brake HMI has changed how press brake operators navigate their careers. The technology makes your talent search more flexible, guarantees more security in the production schedule, and makes a job in the press brake department an attractive offer for someone who is able to operate a smartphone. Even if you’ve never touched a press brake, you’ll be able to bend your first part after only five minutes—all thanks to a smart, user-friendly control interface.

By: Marcel Fiedler, Product Manager - Bending, Bystronic Inc. As published in The Fabricator, July 2020.