Autonomous and profitable at an unbeatable price Laser cutting machines that include free tools

Your advantages

The highest profitability with Bystronic laser cutting machines Making sure your cutting process remains competitive

With high-precision laser cutting machines, you can cut at 2 to 20 kilowatts. The smart functions featured in the parameter wizard and nozzle control tool (NCT) ensure a high level of process reliability due to greater autonomy, even with low numbers of operators and inexperienced employees.

More profitability thanks to:

- Highest part precision

- Less rework

- Shorter operator training time

- Reduced processing time

- Less material waste

Take advantage of our limited offer!

Our unbeatable limited edition offer

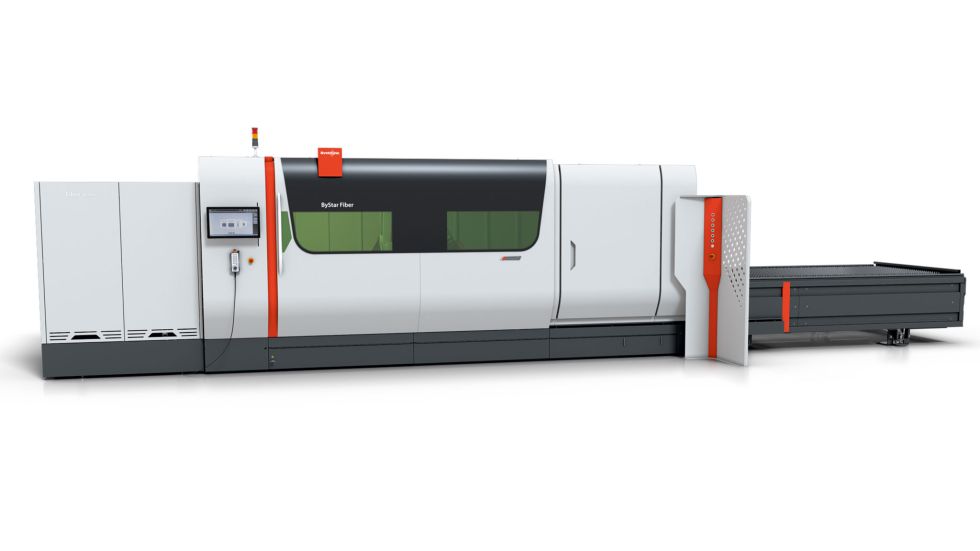

ByStar Fiber 3015 and 4020 Our high-speed laser cutting machine

ByStar Fiber revolutionizes your production processes, even with challenging parts and materials. With an impressive output of between 2 kW and 20 kW, you can handle orders at record speed without compromising quality. The cutting heads are Swiss made and guarantee excellent results even for the toughest applications.

ByStar Fiber is so versatile that it can handle metals ranging from steel to copper base alloys with a plate thickness of up to 50 mm. Because the machine provides intuitive user guidance with touchscreen operation, you can upgrade quickly and save precious time.

ByStar Fiber technical data

| ByStar Fiber | 3015 | 4020 |

| Nominal sheet size | 3000 × 1500 mm | 4000 × 2000 mm |

| Maximum simultaneous positioning speed | 170 m/min | 170 m/min |

| Maximum workpiece weight | 1100 kg | 1900 kg |

| BySoft Cell Control Cut operation and manual control unit | | |

BySmart Fiber 3015 Compact and straightforward

With up to 12 kilowatts of laser power, the BySmart Fiber offers outstanding cutting performance. Its pioneering technology and intuitive user interface make it easy to get started.

Your advantages:

- Rapid part output

- Optimized, accelerated production process

- Fast, accurate and cost-saving

- Cuts a wide material mix from thin sheet to medium thickness plate

- Low operating costs

- Low maintenance costs

BySmart Fiber 3015 technical data

| BySmart Fiber 3015 | |

| Nominal sheet size | 3000 × 1500 mm |

| Maximum simultaneous positioning speed | 140 m/min |

| Maximum workpiece weight | 1100 kg |

| BySoft Cell Control Cut operation and manual control unit | |

Increase your profitability now by reducing your costs with our laser cutting machines that include free tools. Give us a call for a quote.

Free tools Available when you buy one of our limited edition laser cutting machines

Parameter wizard

The parameter wizard makes sure the cut parts are of optimum quality. This is done with precision by determining the perfect parameters in just a few minutes.

That is how you can minimize the costs for each part.

Nozzle control tool (NCT) with KerfScan

The nozzle control tool (NCT) enables you to quickly and reliably angle the nozzle and monitor its status. KerfScan checks the cutting process while flame cutting steel, and solves any problems that it detects.

This combination ensures a stable process without the operator having to intervene.