Smart detection of compressed air leaks

With the help of an intelligent algorithm

Leaks in compressed air systems can quickly cost companies tens of thousands of euros every year. An intelligent algorithm can help.

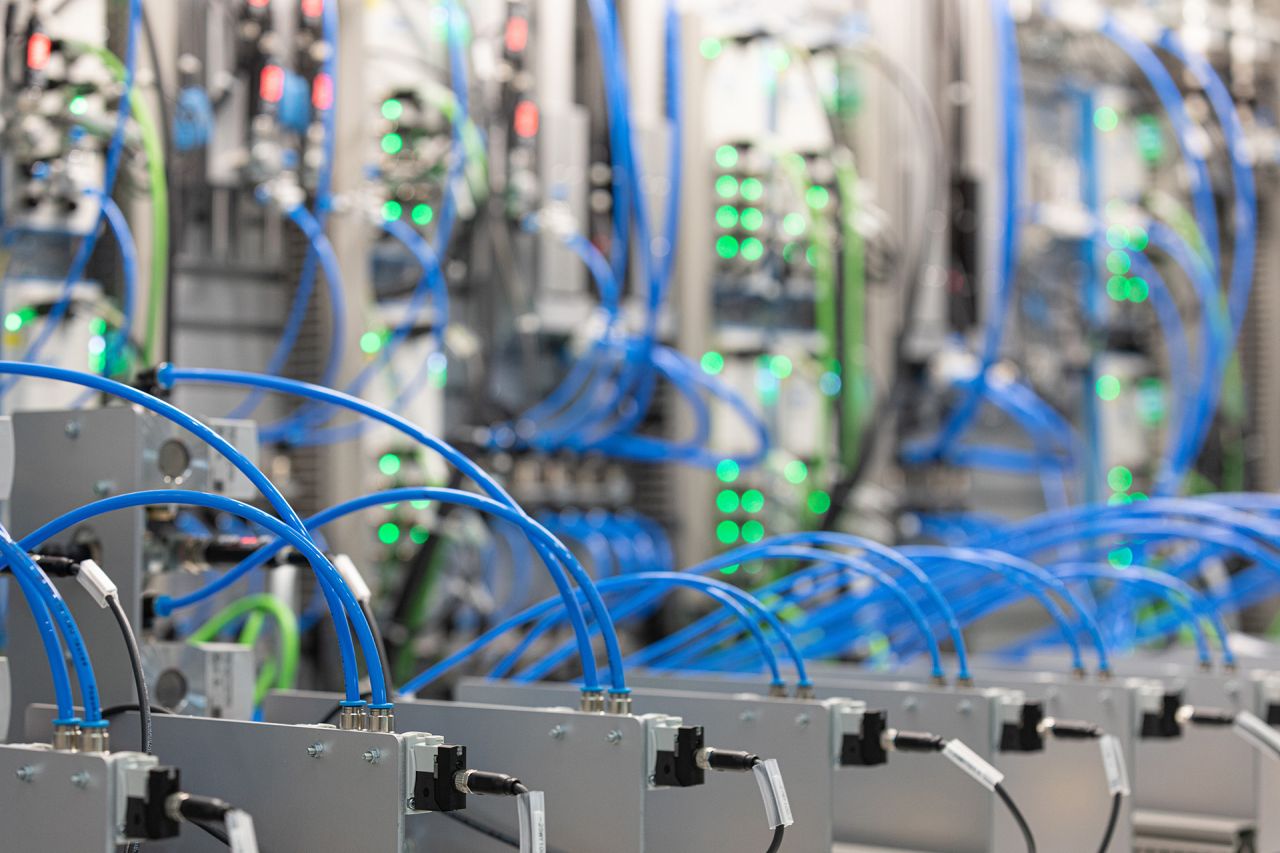

The Fraunhofer Institute for Manufacturing Engineering and Automation estimates that a third of the compressed air produced in industrial companies escapes unused. The energy potential that is lost through leaks and leaky connections corresponds to around seven percent of the total electricity consumption of German industry. The cost of this waste can quickly amount to tens of thousands of euros per company per year.

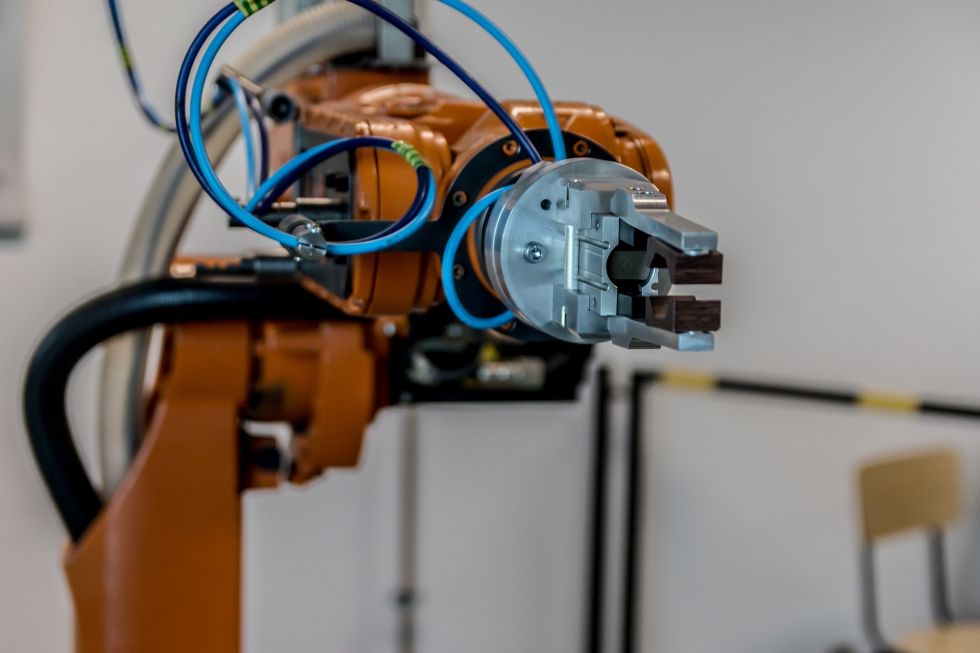

A research team from Fraunhofer IPA and the Institute for Energy Efficiency in Production at the University of Stuttgart, together with an industrial partner, has now developed a method for the automated detection of leaks in pneumatic machines and systems. At its heart is a flow sensor that is connected to the compressed air supply line of a machine and continuously records the mass flow, pressure and temperature curve. An intelligent algorithm evaluates these curves in real time and recognizes characteristic signatures that indicate leaks.

The research team is confident that this automated detection can reduce energy loss by an average of around ten percentage points. However, it will be some time before the solution is ready for series production. The project's intelligent algorithm has been fully developed and has proven that it works reliably during operation. But there is no market-ready product yet.