News A group sees the light of day

Text & photo: Industribilder.se

A complete engineering industry

On Maskinvägen in Byske, there are welding robots, bed mills, multi-operation machines and many other large machines that impress. A solid edge press that can handle lengths of up to four meters with a pressing force of 400 tonnes rises like a wall in the room before reaching the most powerful fiber laser north of Mjölby.

Collaboration creates gains and strength

The site manager in Byske is called Anette Lindgren and shows around at the same time as she talks about the group formation. The various companies are spread across the country, including Smedjebacken in Dalarna 800 km south. Having a piece of the puzzle in the company so far away is no problem. We manufacture many construction details here in Västerbotten and send them in flat packages to Dalarna where they are further processed and assembled together for the end customers who are all over the country.

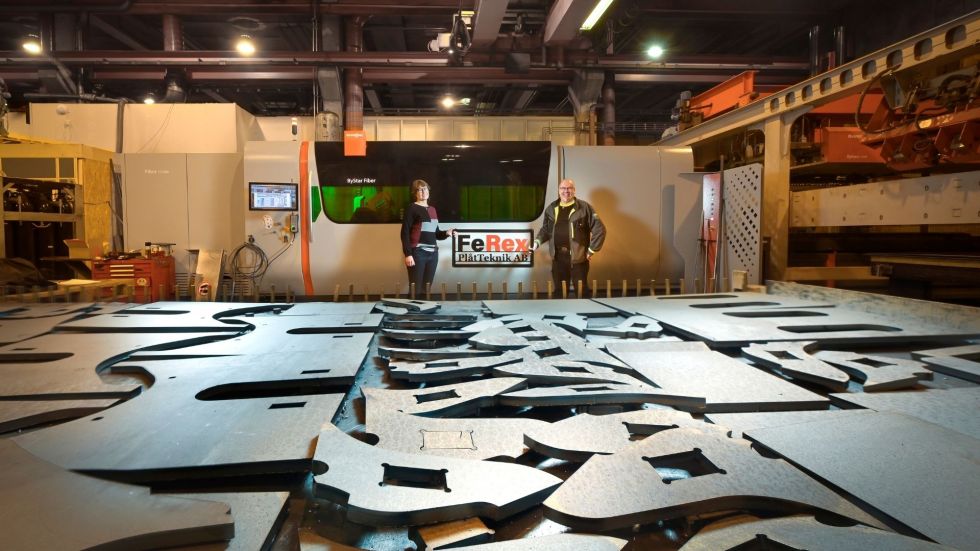

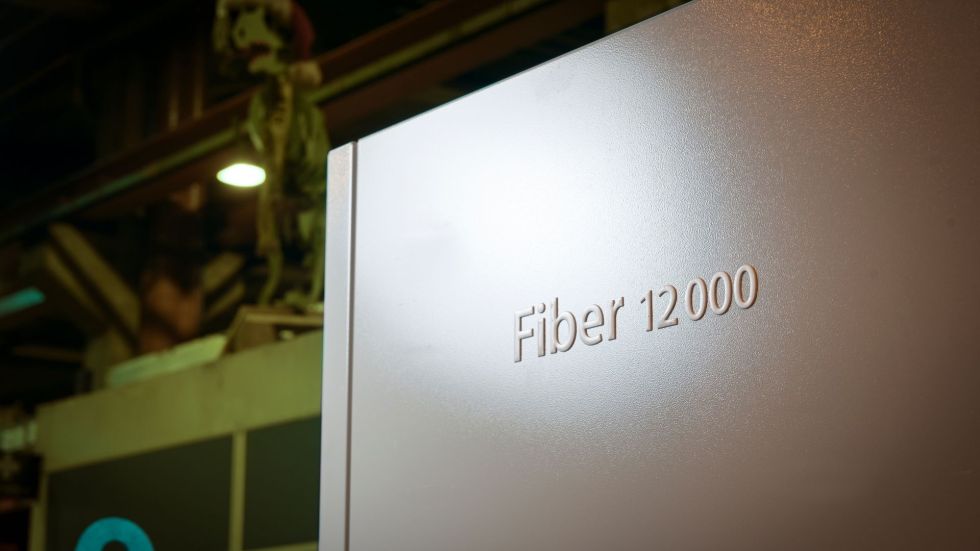

About 50 people work in Byske and in the 8,000 square meter premises, operations have been ongoing since 2003. Now in September, the newcomer - a powerful building block in the company - has taken place. The impressive 12 kilowatt strong fiber laser from Bystronic dominates the room it stands in.

Powerful shining star in northern Sweden

Hans Sundqvist, owner of FeRex AB, has been responsible for the procurement of the 12 kilowatt equipped laser cutting machine ByStar Fiber and Jörgen Lundqvist, who is responsible for FeRex PlåtTeknik, feels satisfied now that it is in place.

It is the fourth laser since 2004 when a 2.8 kilowatt was installed. Our large press brake also comes from the same manufacturer and we have had a good collaboration with Bystronic since the start. Now it feels safe to step into the future with this investment.

Jörgen Lundqvist

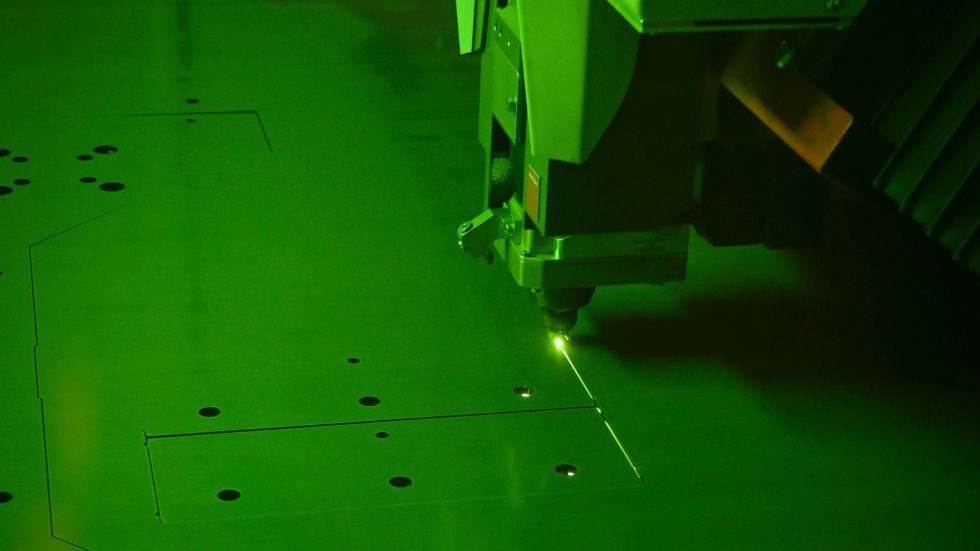

BeamShaper sets a new standard for stylish cuts

An accessory that is completely new on the market was chosen for the impressive 12 kilowatt fiber laser. A BeamShaper is placed in the newly designed cutting head and gives a very fine cut in the coarsest plates from 15-30mm. In addition, it cuts quickly. Very fast! The laser operator Philip Sundqvist states that the bottleneck is not in the laser cut.

We can produce more pieces faster, which makes the picking a bottleneck. A good rating for the fiber laser.

Philip Sundqvist

The facility also includes an automation facility, a high-bay warehouse with 30 cassettes where 3 tonnes of sheet steel can be accommodated in each cassette.

Produces to the fullest

The customers then, who are they? A picture on the wall by the office shows protective gates and claws on forest machines from Komatsu and Anette says that even in the house more details are made for the forester himself. In the same building is also Renholmen, which designs production lines for the sawmill industry. ABB is also a major customer for which switchgear manufacturers are used. Of course we are good at large and rough sizes, but we also manufacture a lot in sheet metal down to 3mm. We are complete, say both Anette and Jörgen.

Company facts

FeRex AB

Is a complete engineering company with expertise from idea sketch to finished product. Owner Hans Sundqvist. The parent company in Byske was formed in 1984. The company group includes FeRex PlåtTeknik in Byske and FeRex SvetsTeknik and FeRex Zink located in Smedjebacken. The number of employees in the entire group is 90 people and sales for 2021 are around 140 million.

Bystronic Scandinavia AB

Was founded in 1989 and is the Bystronic group's sales and service company for the Nordic and Baltic countries. Bystronic is one of the world's leading suppliers of sheet metal processing solutions and offers a comprehensive range of high-tech machines and systems. Bystronic stands for reliability, high performance, innovations, cost efficiency and user-friendly operation.