News The reloading genius

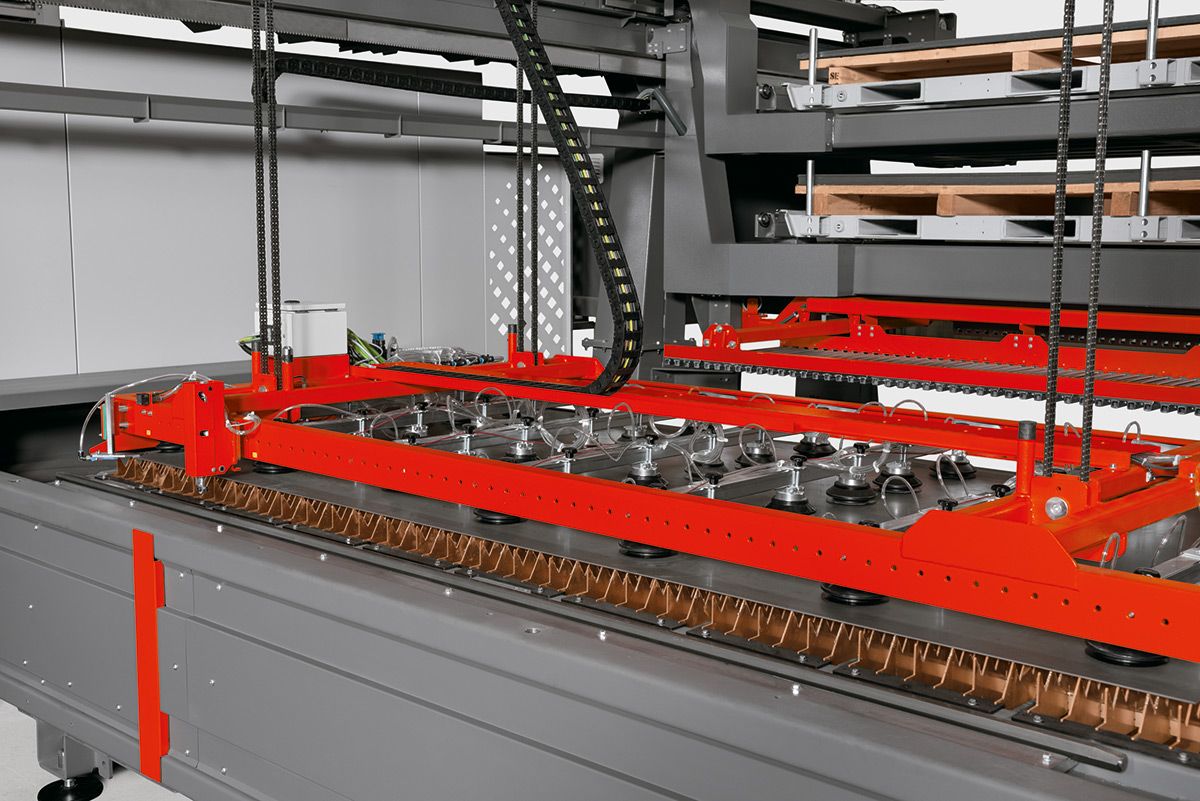

With the ByTrans Cross, Bystronic has developed a new loading and unloading solution for laser cutting. What makes it so special is the great freedom it offers users. The ByTrans Cross has accomplished the balancing act, which has, until now, always pushed conventional automation approaches to their limits: automation for large series and simultaneously sufficient flexibility for small jobs. The modular design of the ByTrans Cross opens up several possibilities for users to integrate the loading and unloading system into their manufacturing environment.

Possibility 1: The ByTrans Cross can be connected to existing warehouses as an integrated loading and unloading solution. In this constellation, the automation solution forms a bridge between the warehouse and the laser cutting system.

Possibility 2: The ByTrans Cross can also be used as a stand-alone solution without connection to the warehouse, in order to provide the laser cutting system with raw metal sheets in various thicknesses and materials. The basic version of the ByTrans Cross comes with two cassette carriages, which can be used to store raw material. However, it is also possible to use just one cassette carriage for the storage of raw material while the second carriage can be used to deposit the cut parts.

Possibility 3: Whenever users want to process spontaneous jobs without interrupting the automated process, the ByTrans Cross offers sufficient freedom to load metal sheets onto the laser cutting system’s shuttle table or unload finished parts by hand or overhead crane. This is made possible thanks to the system’s slim design. The ByTrans Cross is positioned on the side of the laser cutting system’s shuttle table. This even makes it possible to load metal sheets using a fork-lift truck.

Smart operation provides convenience for users

The seamless integration of laser cutting into the up and downstream processing steps, of which the rhythm can change at any time, is an additional important aspect that the ByTrans Cross solves optimally. This is possible thanks to the integration of the automation system’s control into the laser cutting system’s user interface. This enables users to start the cutting process and the automated material flow with just a few taps on the laser cutting system’s touch screen.

To achieve this, Bystronic developed the ByVision Cutting user interface, which is already successfully being used with the latest generation of Bystronic’s fiber lasers. ByVision Cutting integrates all the cutting processes and the associated automation solutions. During everyday production this allows laser cutting and the automated material feeding and removal process to be seamlessly interlinked. Nowadays, no user should waste time, walk long distances, and carry out unnecessary procedures, just because the laser cutting system and the connected automation solution have to be operated using separate terminals. After all, for the operator, automation also means convenience.