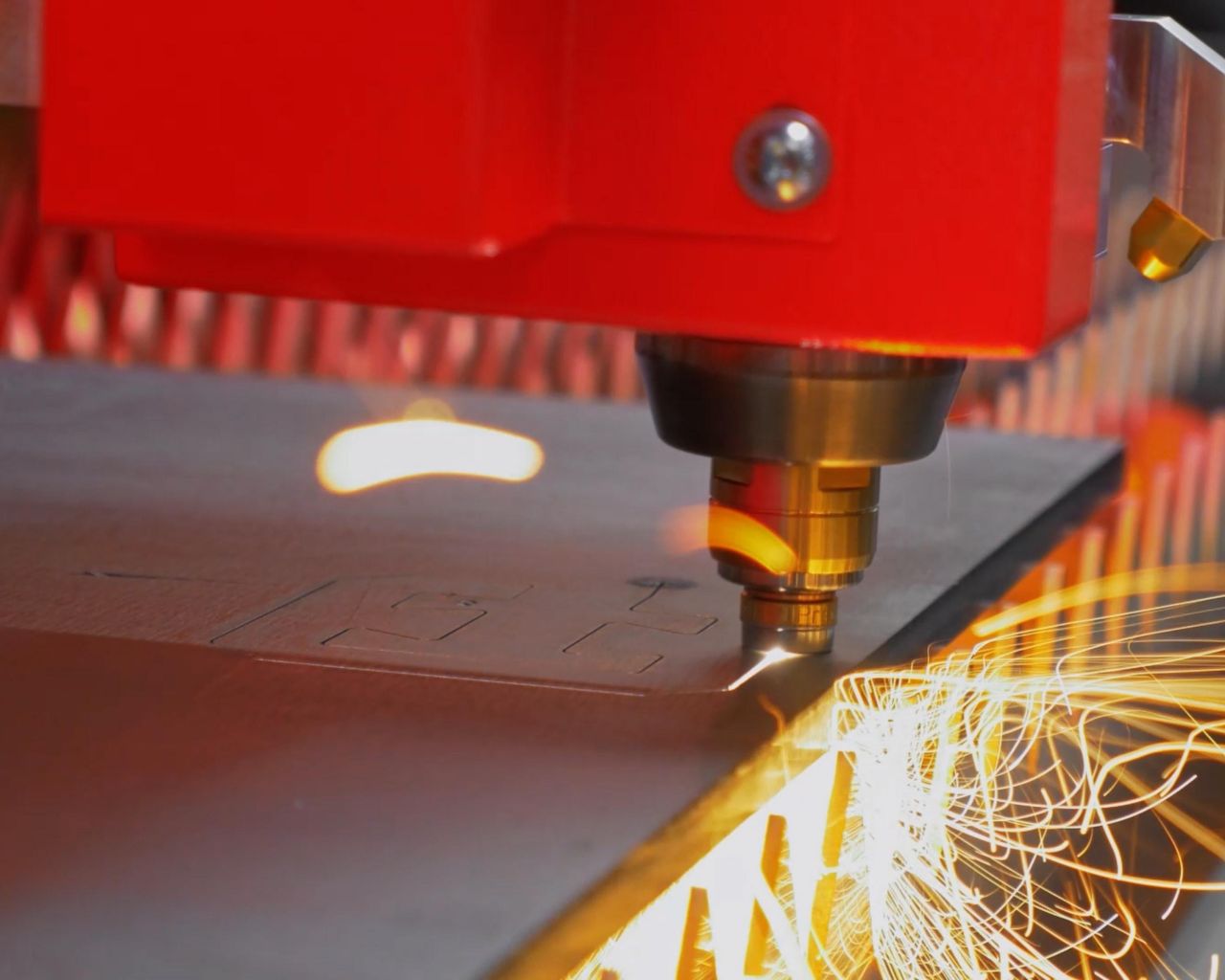

Fiber Laser vs. CO2 Laser Save money with a more energy-efficient machine

In times of energy crisis with increasing electricity prices, there is also an increased necessity for businesses to lower their energy costs.

Industrial operations are left with no alternative but to replace energy guzzlers with modern machines. These can reduce costs on multiple levels at once.

The comparison of the energy-efficient fiber laser vs. CO2 laser demonstrates this.

Fiber laser vs. CO2 laser differences

CO2

The CO2 laser generates a laser beam using a carbon dioxide-based gas mixture. This mixture is stimulated with electricity. At the same time, the laser beam is guided along a beam path using optics.

Fiber Laser

Fiber lasers are solid-state lasers with similar power ranges as their CO2 counterparts. The active laser medium is a glass-like or crystalline fiber or plate. Here, the beam is generated in an active fiber and transmitted via a transport fiber to the machine cutting head.

One of the most crucial differences, in addition to the laser medium, is their wavelengths. These are as follows:

- Fiber laser: 1 µm

- CO2 laser: 10 µm

The shorter wavelength in the fiber laser vs. CO2 comparison leads to a higher absorption rate when cutting steel, inox, and aluminum.

Benefits of a fiber laser in contrast to a CO2 laser

Fiber laser technology has advanced by leaps and bounds in recent years. Its success relies on a complete package of distinct individual factors. When its potential has nevertheless been exhausted, a fiber laser is economically worthwhile for the following reasons:

- It commands a high cutting speed and thus has low operating costs per hour.

- In a direct fiber laser vs. CO2 system comparison, fiber lasers do not require nearly as much energy. Its electrical efficiency is thus up to 5 times greater.

- It sets itself apart with a simplified beam path.

- A fiber laser is low maintenance.

Increase your productivity and lower your costs with our fiber lasers

Potential savings:

Practical fiber laser vs. CO2 sample calculation

Directly comparing fiber laser vs. CO2 system power consumption, it becomes clear how high the potential savings could be.

Savings when replacing a CO2 laser machine

| Target Working Time / Year | Cutting (laser on) | Average Power Consumption | Power Consumption / Year | |

| CO2 Machine (6kW) | 3,600 h x | 65% x | 65 kW | = 152’100 kWh |

| Fiber Machine (6kW) | 3'600 h x | 65% x | 22 kW | = 51’480 kWh |

| Power savings / Year | = 100'620 kWh | |||

Power savings per year

à 0.25 €/kWh: 100'620 kWh x 0.25 €/kWh ≈ 25'000 €

à 0.75 €/kWh: 100'620 kWh x 0.75 €/kWh ≈ 75'500 €

Power savings over a 5-year period

à 0.25 €/kWh: 25'000 € x 5 years = 125'000 €

à 0.75 €/kWh: 75'500 € x 5 years = 377'500 €

Switching from a CO2 laser to a fiber laser can mean annual savings of €25'000 to €75,000.

In this example, a 6 kW CO2 laser is replaced with a 6 kW fiber laser. As the graphic indicates, the CO2 system has three times the power consumption of the fiber laser.

At a hypothetical price per kWh of €0.25, that results in annual savings of €25'000. Projected over 5 years, the saved costs come to €125'000.

Savings when replacing two CO2 laser machines

| Target Working Time / Year | Cutting (laser on) | Average Power Consumption | Power Consumption /Year | |

| CO2 Machine (6kW) | 3’600h x | 65% x | 65kW | = 152’100 kWh |

| CO2 Machine (4.4kW) | 3’600h x | 65% x | 51 kW | = 119’340 kWh |

| One Fiber machine can replace two CO2 machines! | = 271’440 kWh | |||

| Fiber Machine (10kW) | 3’600h x | 65% x | 25kW | = 58’500 kWh |

| Power savings / Year | = 212’940 kWh | |||

Power savings per Year

à 0.25 €/kWh: 212’940 kWh x 0.25 €/kWh ≈ 53’000 €

à 0.75 €/kWh: 212’940 kWh x 0.75 €/kWh ≈ 160’000 €

Power saving over 5-year period

à 0.25 €/kWh: 53’000 € x 5 years = 265’000 €

à 0.75 €/kWh: 160’000 € x 5 years = 800’000 €

In fact, due to its higher productivity, one laser system replaces the equivalent of two CO2 lasers at once.

The power consumption of a 10 kW fiber laser is only approximately a fifth that of two CO2 machines with the same power. Taking this into account, it results in savings of €53,000 per year and €266,000 over 5 years.

The results of a fiber laser vs. CO2 comparison are thus very clearly in favor of the fiber laser.

Save double as much:

Benefit from free Smart Features

For a limited time, we are also offering you our Smart Features free of charge when you switch from a CO2 machine to a fiber laser machine from Bystronic.

Benefits of the Smart Feature:

Parameter Wizard

The Parameter Wizard is an AI-based function that supports less experienced operators to find and optimize the perfect parameters in a matter of minutes.

Customer benefits of the Smart Feature:

NCT & KerfScan

The Nozzle Control Tool (NCT) makes it possible to center nozzles rapidly and reliably. KerfScan examines the process during flame cutting.

Using both tools thus enables the following:

- High autonomy during lightly-manned operation

- Consistently high process quality during flame cutting

- Reduced set-up time

- Reduction of scrap

- Easier removal of parts for automatic sorting

Use the following promo code to take advantage of this one-time offer: GOSmart23